Rematerializing wood waste to produce beautiful end-use products

The Forust process combines two wood industry byproducts - sawdust and lignin - to produce isotropic, high-strength, sustainable wood parts.

-

High-quality materials and finishes

Unlike particle board or laminate, Forust produces 3D printed, digitally rematerialized wood, with grain that flows across the entire part and can be sanded and refinished. The Forust process has the ability to mimic almost any wood grain, from Ash to Zebrano, Ebony to Mahogany.

-

Streamlined production of complex wood designs

3D printing opens a new design space for wood-based products. Because parts are formed layer by layer without the need for supports, designers can optimize parts and create complex features which would be difficult - if not impossible - to achieve with traditional woodworking methods.

-

Cost-effective carbon footprint reduction

Forust processes and materials are designed to make it easy and cost-effective for manufacturers to produce sustainable wood parts. The Forust process gives manufacturers a fully sustainable solution at costs competitive with traditional wood manufacturing.

Make sustainable wood products in volume

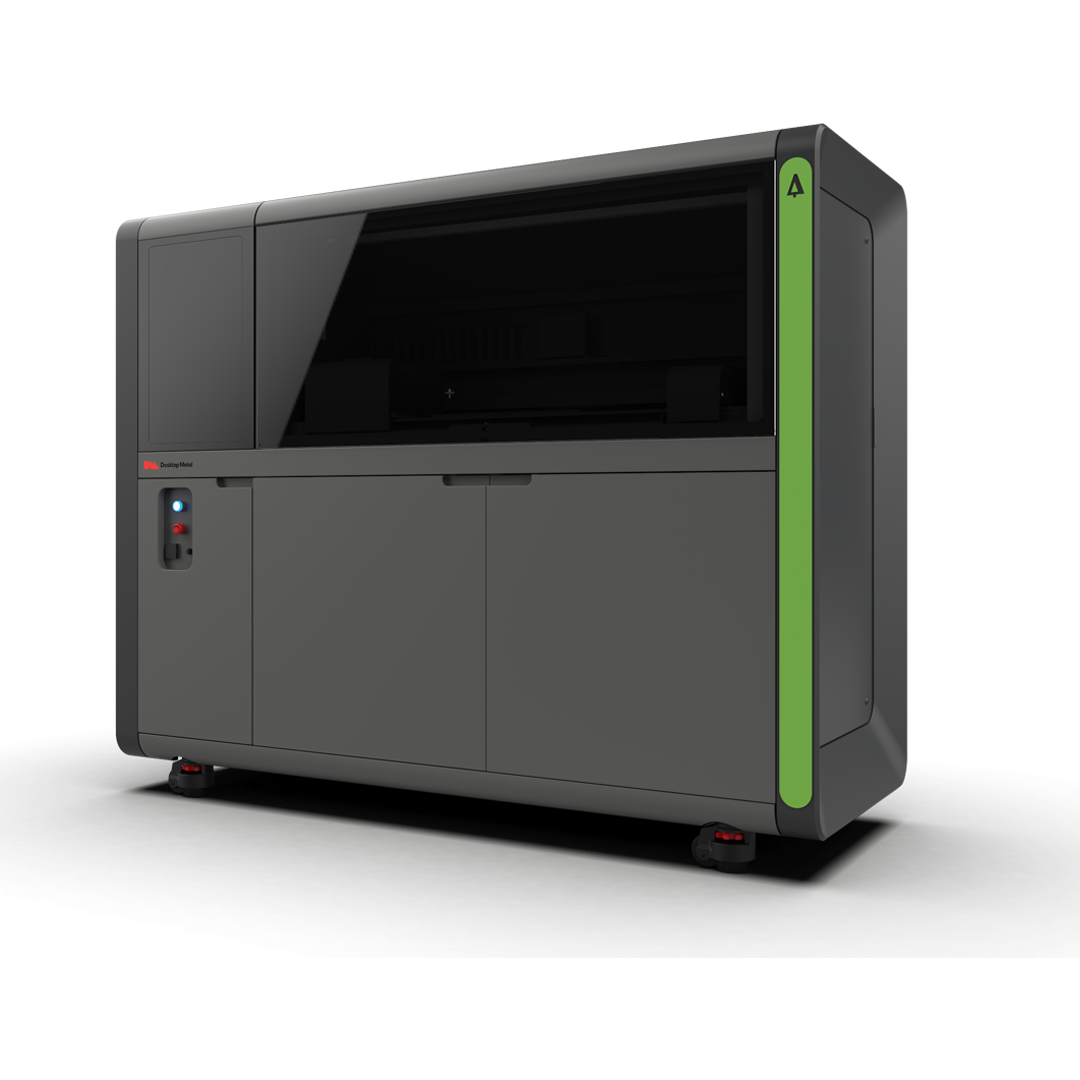

Shop Forust products, order quantities of custom designs, or scale-up manufacturing in-house with the purchase of a Shop System™ Forust Edition.

Applications

From everyday home goods to high-end architectural detailing, Forust can create parts for virtually any application where wood parts are used.

The on demand 3D printing of wood using waste natural materials is a gamechanger. By allowing millions of trees to remain in place in their forests, Forust is launching a highly evolved technology for the circular technosphere. We have only begun to explore its beneficial potentials, but it is clear they are immense.

”